SYSTEM

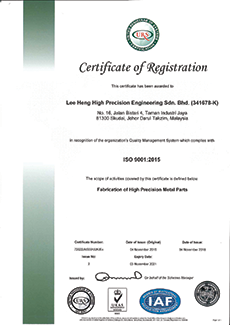

QUALITY MANAGEMENT SYSTEM

Our team is fully committed to a total quality management and continuous improvement philosophy. It begins with the careful review of project specifications and the exhaustive inspection of first article components, and continues to the ongoing evaluation of finished product.

- Full traceability of materials used

- Full article inspection reports

- Certification of conformity provision

- PFMES's control plan & process flow chart

- Comprehensive quality assurance system

- Guaranteed high quality products

INSPECTION & EQUIPMENT?

- Ensuring the accuracy of precision engineered components is critical for their application in most circumstances; we provide full inspection of our own components and those made by others.

- Quality permeates everything we do, from materials grade checking at goods inwards right through each part of the design, development and production processes, to final quality testing at each phase.

- We inspect raw materials, processes and final products to ensure we meet our customer requirements. We demonstrate full traceability of materials and processes and providing detailed reports to prove that our processes are carried out as per customer requirements. All relevant documentation is held on our ERP database and can be issued on dispatch of products if required.

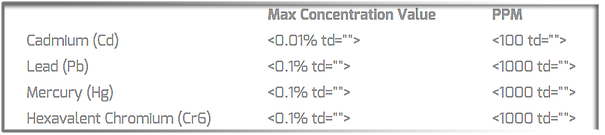

ROHS Directive - 2011/65/EU

As a manufacturer of precision component, LHHP's products need to be compliant with certain requirement such as the ROHS directive from incoming purchase until end customer's delivery.

LHHP practices random checked on RoHs compliance status by quarterly at planned interval for raw material & finished goods at least 3 times each by sending to external accredited laboratory test.

The following elements are hazardous to human health and need to be eliminated on any product being produced.

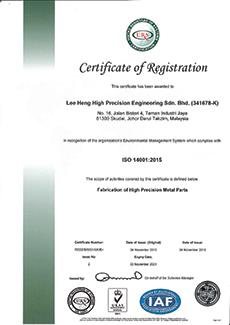

ISO CERTIFICATION